How to select MIG/MAG, MMA and TIG welding processes?

welding speed

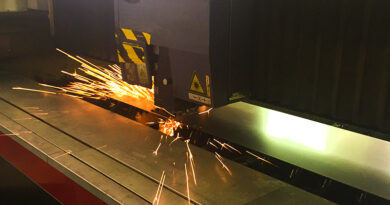

Where mass production is required in a short period of time, high speed may be important in terms of cost-effectiveness. However, high welding speed also means that the heat affected zone on the component is smaller. This area is formed in the weld area, where the heat input of the workpiece will reduce the performance of the metal. Heat can locally harden the metal, making it brittle, causing cracks or fractures, and reducing the tensile strength. Therefore, it is very important to minimize the heat introduced into the base metal. MIG/MAG welding process has the advantages of fast welding speed, good weld quality and wide range of functions.

Weld appearance

Since the weld is clearly visible, a perfect appearance is essential. Smooth fish scale weld appearance and extremely fine texture are usually required. This can only be achieved through special functions of TIG process or MIG/MAG process, such as MIG/MAG seam welding or CMT. In manual arc welding, the appearance of the weld depends on the type of electrode used.

QUICK LINKS: FAQ | Inside Corner Bracket | Power Distribution Cabinet | Sheet Metal Products | Sheet Metal Service | Corner Bracket for Cabinet | Outdoor Telecom Cabinet | Sheet Metal Parts Pricelist | Sheet Metal Parts Components | Powder Coating Small Parts | Anodized Black Aluminum Cover