Sheet metal inspection is the process of evaluating and verifying the quality, accuracy, and conformity of sheet metal parts to ensure they meet the specified design requirements and industry standards. This process involves various checks and measurements to confirm that the fabricated parts are free from defects and are within the acceptable tolerances and specifications outlined in the engineering drawings.

Key aspects of sheet metal inspection include:

- Dimensional Inspection: Measuring the physical dimensions of the sheet metal parts, such as length, width, thickness, and angles, to ensure they match the design specifications. This can be done using calipers, micrometers, coordinate measuring machines (CMM), or other precision tools.

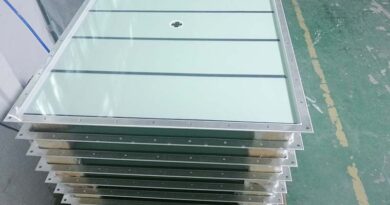

- Visual Inspection: Checking for surface defects like scratches, dents, cracks, or warping that could affect the part’s functionality or aesthetic quality. Visual inspection can be done with the naked eye or with the aid of magnification tools.

- Bend and Form Accuracy: Verifying that bends, curves, and other formed features are within the specified tolerances, ensuring the part will fit and function correctly in its intended application.

- Hole and Cutout Inspection: Ensuring that holes, slots, and other cutouts are in the correct locations, have the correct dimensions, and are free of burrs or other imperfections.

- Surface Finish and Coating Inspection: Evaluating the surface finish to ensure it meets the required specifications, such as roughness, texture, or coating thickness. This may involve measuring the thickness of coatings like paint, anodizing, or plating.

- Weld Inspection: If the sheet metal part involves welding, the welds are inspected for proper penetration, bead appearance, and absence of defects like cracks or porosity.

- Functional Testing: In some cases, parts may be subjected to functional tests to ensure they meet operational requirements, such as load-bearing capacity, flexibility, or resistance to environmental factors.

Sheet metal inspection is crucial for maintaining quality control in manufacturing, preventing defects, and ensuring that the final product meets the necessary standards for safety, performance, and reliability.

These metrics help ensure that the fabricated parts meet design specifications and perform as intended.

Click sheet metal fabrication company china or china sheet metal forming manufacturers to learn more about sheet metal fabrication services.

For all your electrical enclosures from China, contact china sheet metal fabrication factory JIATONG now.

From Sheet Metal Fabrication Companies in China, china sheet metal fabrication manufacturers, china sheet metal fabrication companies – JIATONG