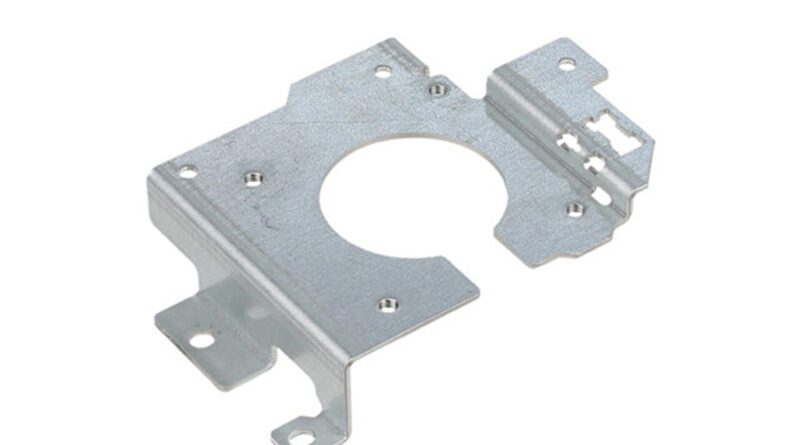

Design criteria of sheet metal structure

According to the problems encountered in the actual machining process, the problems needing attention in the structural design of sheet metal are discussed from the following aspects, and the corresponding design criteria are given.

- Selection criteria of sheet metal materials

Sheet metal is generally used for the installation of equipment shell and electrical circuit, so it is very important for the selection of sheet metal. Proper selection is not only conducive to processing, but also can reduce the cost on the premise of ensuring the strength.

(1) In order to ensure the material utilization rate and the minimum number of die changes in bending, the thickness specifications of plates on the same structure shall not exceed three at most. For structures with high strength requirements, the method of pressing reinforcement on thin plates can be adopted;

(2) It should be avoided that the unfolding size of parts is equal to the outline size of raw materials: the shape of plates supplied in the market is not square. If the unfolding size is equal to or very close to the outline, there is no allowance for the whole square, and the product size after direct processing has errors, which will affect the installation and use.

(3) For non-sprayed plates with decorative surface requirements, the decorative surface and grain direction shall be considered in combination with the plate materials. For any purpose, the plate with decorative surface shall be used and the grain direction shall be required. For non-exposed parts, the processing process shall be protected from scratch, and the welding joints shall be treated after welding. The processing volume is large. Therefore, in order to ensure the utilization rate of materials and reduce unnecessary processing, The direction of decorative surface or other materials without decorative surface can be ignored.

Custom Metal Fabricators Near Me | Custom Metal Fabrication | Sheet Metal Custom

- Design criteria for hole structure

For the design of holes, in addition to meeting the product requirements, they shall meet the requirements of easy processing or not affecting the subsequent process and beauty after processing.

(1) Try to avoid opening the square hole to the bending root: the stretching of the plate after bending will lead to hole deformation. If the hole is made manually, it will increase the processing difficulty.

(2) The processing method of screw hole can be realized by different methods: direct tapping on plate; Flanging tapping; Riveted nut; Spot welding of nuts and other methods, specific different sheet thickness and screw hole size should be different methods.

The structural design of sheet metal equipment is closely related to the production process. With the improvement of the automation of sheet metal equipment, we need to constantly understand and contact new sheet metal knowledge, which provides a guarantee for better processing technology of designed parts in the future. In order to ensure the quality of the products and improve the competitiveness of the enterprise in the industry, the processing cost can be reduced as much as possible.

QUICK LINKS: FAQ | Stainless Steel Sheet Metal Fabrication| Metal cases Aluminum case suppliers | Alu Bracket | Sheet Metal Custom | CNC Stamping Parts | OEM Custom Radiator Support Bracket | Metal Frames | Sheet Metal Chassis | Mounting Bracket |