Common problems of sheet metal processing stamping parts

The sheet metal stamping process converts hot-rolled or cold-rolled steel plates into the shape needed to make your parts. This technology allows a large number of parts to be produced at the same time, but it can also cause about 15% of raw materials to become waste. The equipment used in this method requires less space than other methods, so if your space is limited, this type of manufacturing may be most suitable for your enterprise. When using sheet metal stamping, three types of dies are mainly used — cutting, punching and bending.

Cutting involves cutting a part from a metal plate. This is accomplished by striking the metal plate with a die, which cuts the metal plate into the desired shape. The edges of punched parts will have burrs, so they need to be filed or processed before use.

Punching is to punch a hole in the metal plate by placing the metal plate between two dies and forcing them together.

Bending is the deformation of metal by using the pressure of the die. This type of stamping is often used to make curved parts.

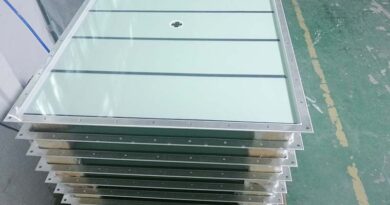

LED Display Controller Box | Aluminum Electrical Enclosures | Storage Server Chassis

Some common questions:

Burr: surplus material is not completely left in the process of punching or corner cutting, and burr occurs under the section of steel plate. When the height of burr is more than 0.2mm based on the section, the iron powder will damage the mold and produce convex and concave.

Convex concave: the surface of the material is abnormally convex or concave, which is caused by the mixing of foreign matters (iron filings and dust) in the uncoiling line.

Roller print: caused by foreign matters attached to the cleaning roller or feeding roller (with a fixed pitch). Generally, the foreign matters on the roller print on the sheet can be removed.

Slip mark: caused by the sliding of the roller, which occurs when it suddenly stops or accelerates.

Roll crushing and edge wrinkling: the wrinkling situation caused by the small gap between the guide roller on the uncoiling line or the guide roller on the die, which is caused by the non-bending balance of the roll feeding.

Scratch: the main cause of scratches on parts. There are sharp scars on the mold or metal dust falling into the mold. The preventive measures are grinding the scars on the mold and removing metal dust.

Bottom cracking: the main reason for the bottom cracking of parts is that the material plasticity is poor or the die blank holder ring is pressed too tightly. The preventive measures are to replace the material with good plasticity or loosen the blank holder ring.

Wrinkles on the side wall: the main reason for the wrinkles on the side wall of the part is that the thickness of the material is not enough or the deviation occurs during the installation of the upper and lower molds, resulting in large clearance on one side and small clearance on the other side. The preventive measures are to replace the material and readjust the mold in time.

QUICK LINKS: FAQ | 316l Stainless Steel Sheet Metal | Aluminium Cover | Switch Mounting Bracket | Aluminum Rack Panels | Anodized Black Aluminum Cover | Battery Hold Down Brackets | OEM Custom Radiator Support Bracket | Custom Metal Fabrication |TV Back Panel| Custom Rackmount PC |